For the innovation projects Door Leaf Test System (DLTS) and Development Truck Door System, Ventura Systems has received funding

From the so-called Innovative Ambitions Accelerator subsidy or in Dutch: Versneller Innovatieve Ambities (VIA) subsidie. This grant was (partially) funded as part of the Union’s response to the COVID-19 pandemic. On this page we will explain more about these innovation projects.

Door Leaf Test System (DLTS)

Ventura Systems Ventura Systems annually produces thousands of door systems for urban public transport, such as buses and trams. These door systems must all be 100% tested to ensure quality. In order to improve quality, it is necessary to establish a uniform testing system. The DLTS project aims to set up an automated test system, which will test all door systems for the same quality regardless of which operator is involved. To achieve this, four components were developed: User interface web page, PC application, and 2 electronic components with associated embedded applications.

The first phase of the project was to research possible solutions

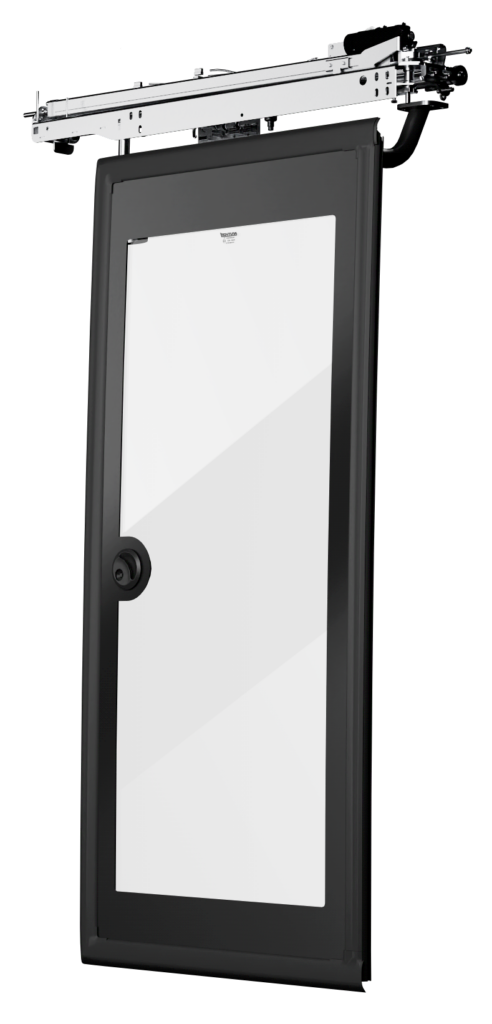

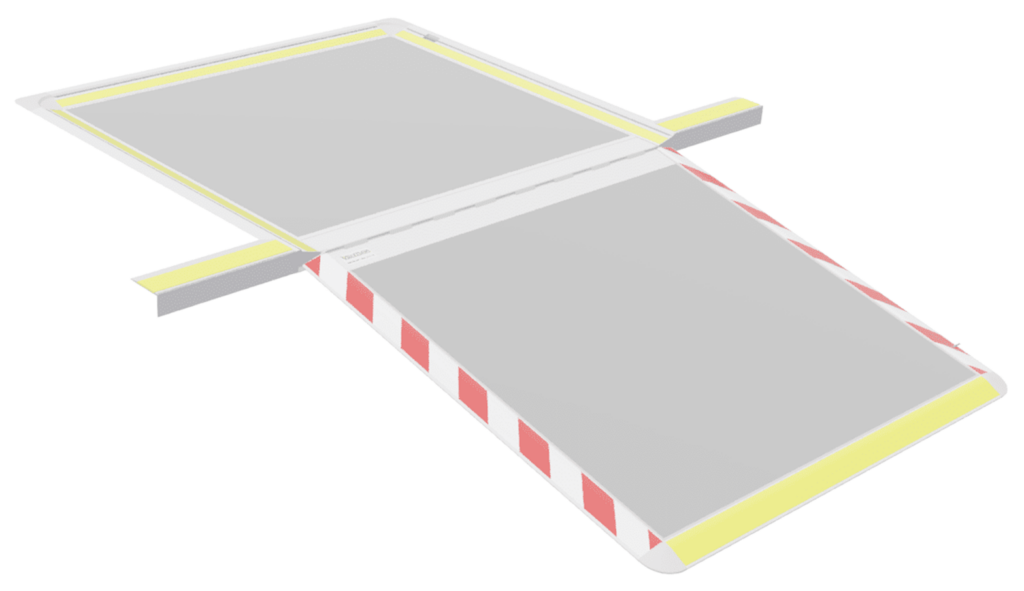

Development Truck Door System

Ventura Systems annually produces thousands of door systems for urban public transport, such as buses and trams. Ventura wishes to extend their product range by developing a door system for trucks.

trucks get large glass doors

New trucks that are used for last mile delivery in urban areas will have to be equipped with large glass doors in order to reduce blind spots en increase safety of cyclists and pedestrians. Because door systems for trucks are significantly different from doors used in buses, Ventura will develop an entirely new door system specifically for use in trucks.

working prototype

The first phase of the project consisted of developing the technical specifications of the system and making several designs. The system features several new concepts, such as manual emergency locking of the door, new sealing rubbers and an entirely new drive system. In the next phase, a prototype of the system was developed. Iteratively, several changes and improvements to the design were made as well. Consequently, the system was thoroughly tested and several parts were redeveloped.

Finally, thanks to funding from the European Union and Partnership Noord-Nederland, we were able to create a working prototype that can be used towards commercialization of the system.