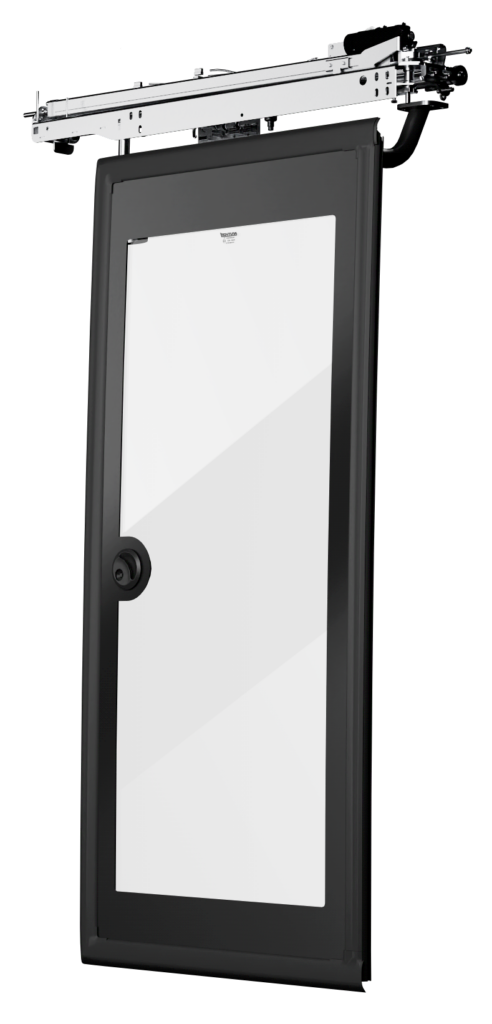

the reliability challenge

For operators, a door is not just a door — it is one of the most failure-sensitive systems on the vehicle. A single door fault can take an entire bus out of service.

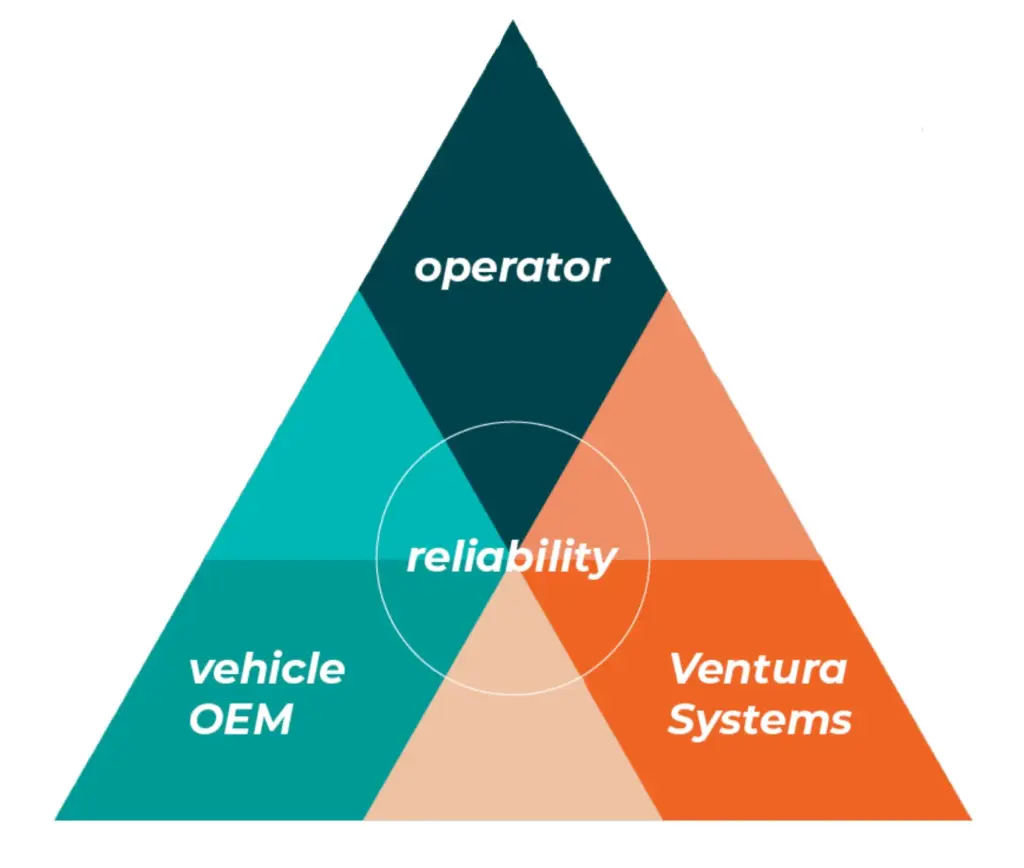

True reliability is created when OEMs, operators and Ventura Systems work as one.

the Reliability Triangle

Ventura builds reliability into every link of the ecosystem:

- Vehicle OEMs provide the platform and vehicle integration

- Operators manage daily service and fleet operation

- Ventura Systems supplies the door systems, engineering, testing, parts and support

At the centre of this triangle is one goal: maximum uptime.

Built-in reliability

Built-in reliability ensures that every Ventura door system delivers dependable performance, supported by proven engineering, original parts, and long-term service expertise.

Ventura designs, tests and validates every door system for long-term durability. From first build-in to continuous monitoring, our systems are engineered to survive millions of cycles under real-world conditions.

Original spare parts, diagnostics, training and technical support ensure that reliability is maintained throughout the entire vehicle life cycle.